The “Mother Machine” in Industrial Manufacturing: Why Are Molds So Important?

Within modern industrial systems, molds are often revered as the “Mother of Industry” or an “Efficiency Multiplier.” While they are not the final product, they are the critical enabler that determines whether a product can be manufactured efficiently, precisely, and economically. From the tiny leads on a semiconductor chip to the complex housing of a smartphone and even to the entire body of an automobile, the creation of almost every mass-produced industrial item relies fundamentally on molds. This article provides a rational analysis of the indispensable importance of molds in industrial manufacturing.

Part 1: What is a Mold? Core Definition and Function

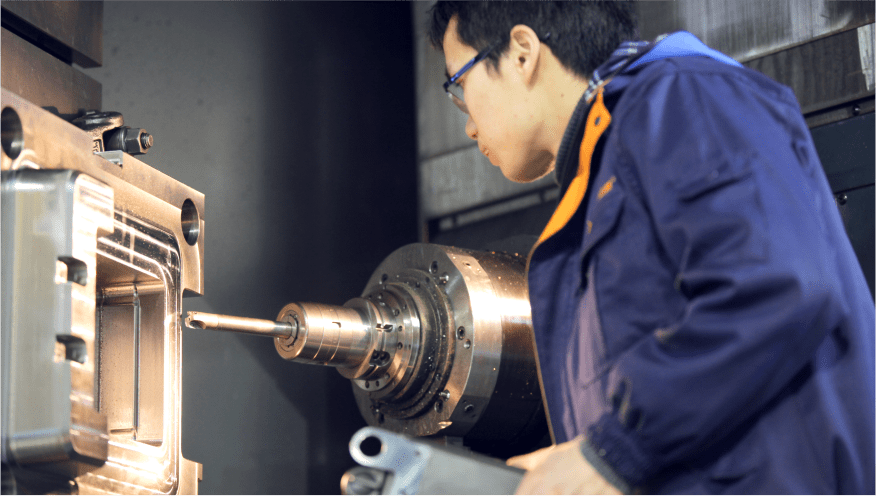

A mold is a specialized tool whose primary function is to give a material its specific shape, dimensions, and surface quality. In essence, it is a “form” with a precise cavity. By introducing material—such as metal, plastic, or ceramic—into this cavity under force or pressure, the material is shaped into the desired component.

Molds are categorized by process, with major types including:

Stamping Dies: Used for cutting, bending, and forming metal sheets (e.g., car doors, appliance panels).

Plastic Injection Molds: Molten plastic is injected into a cavity where it cools and solidifies (e.g., consumer product casings, electronic parts).

Die-Casting Dies: Molten metal is forced under high pressure into a mold cavity (e.g., engine blocks, gear housings).

Forging Dies: Hot metal is shaped by compressive force within a die cavity (e.g., hand tools, crankshafts).

Part 2: A Rational Analysis of Mold Importance

The significance of molds is not merely symbolic; it is fundamentally rooted in modern manufacturing’s relentless drive for precision, efficiency, cost-effectiveness, and consistency.

1. The Ultimate Guarantor of Precision and Complexity

Molds serve as the physical bridge that transforms a digital design into a tangible part. A high-quality mold can maintain cavity tolerances at a microscopic level (microns). This allows for the stable, repeatable production of parts with intricate geometries, fine surface details, and critical mating features—a level of accuracy impossible to achieve consistently through manual methods. The precise fit between a smartphone’s components, for instance, is made possible solely by the extreme accuracy of its molds.

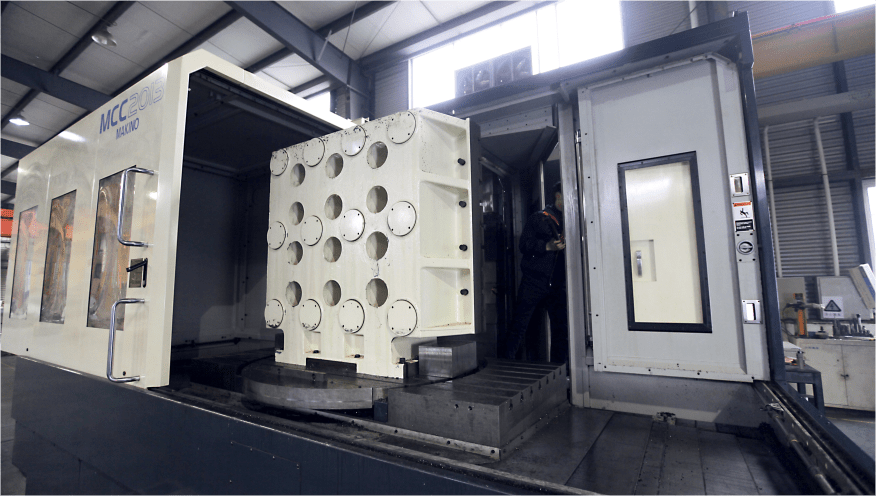

2. The Engine of Mass Production Efficiency

This is the most direct economic benefit. Once a mold is crafted and调试完成, it can be installed in a press or molding machine, producing parts in cycles that can take just seconds. This contrasts starkly with artisanal production. A single stamping press with a mold can output hundreds of parts per minute, whereas manual fabrication might yield only dozens per day. Molds enable the shift from variable, skill-dependent craftsmanship to predictable, high-speed industrial manufacturing, forming the very foundation of mass production.

3. The Foundation for Material Efficiency and Cost Control

In processes like metal stamping and plastic injection, mold design is paramount for material utilization. Intelligent design of the mold layout and material flow channels minimizes waste scrap. In automotive stamping, for example, advanced mold design can increase sheet metal utilization to over 80%, leading to substantial raw material savings. Although the initial investment in a high-precision mold is significant, this cost is amortized over hundreds of thousands or millions of parts, driving the per-unit cost down to a fraction.

4. The Guardian of Product Quality and Consistency

For consumers and manufacturers alike, product reliability depends on uniformity. Molds are the key to this consistency. Provided the mold is maintained and process parameters are stable, the one-millionth part produced will have virtually the same critical dimensions and properties as the first. This unwavering consistency is essential for building brand trust, enabling automated assembly lines, and ensuring the safety and reliability of mass-produced goods.

5. The Enabler of Design Innovation and Rapid Iteration

The feasibility of manufacturing often dictates design possibilities. Advances in mold technology, such as multi-component molding or gas-assisted injection, directly unlock new opportunities for designers to create stronger, lighter, or more complex integrated parts. Furthermore, techniques like mold flow simulation and rapid tooling allow for faster prototyping and design validation, dramatically shortening the time from concept to mass production.

Part 3: Conclusion: The Indispensable Industrial Foundation

In summary, the paramount importance of molds lies in their role as the central link between design and production, innovation and commercialization, precision and scale. They represent a concentrated, upfront engineering investment that defines and secures the quality, cost structure, and production capacity for a product’s entire lifecycle.

Consequently, the capability to design and manufacture advanced molds is a key indicator of a nation’s manufacturing prowess and industrial competitiveness. A robust mold industry signifies the ability to translate innovative ideas into high-quality, affordable products at scale. Though hidden from view in the final product, molds are rightfully honored as the essential “Mother of Industry,” silently underpinning the modern world of manufactured goods.