Engineering Excellence: The Industrial Foundation of Aimbon’s Product Quality

As established, molds are the “Mother of Industry,” the critical link between innovative design and mass-produced reality. They determine the ultimate precision, consistency, and complexity of any manufactured good. At Aimbon, this principle is not just understood—it is the bedrock of our manufacturing philosophy. Our industry-leading mold-making capability and integrated industrial system are the fundamental reasons why Aimbon products deliver exceptional, reliable performance.

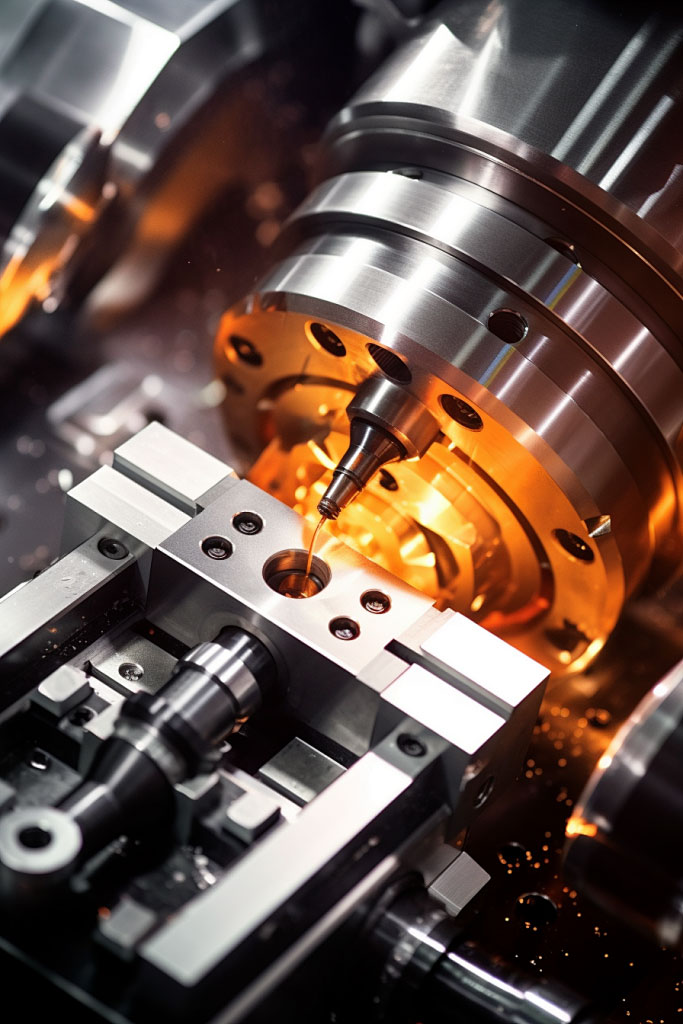

1. Precision Tooling: Translating Complex Designs into Reality

Aimbon’s mastery begins with our ability to engineer and produce molds of exceptional fidelity, which allows us to manufacture highly complex components consistently.

Micro-Scale Precision for Core Technologies: Our proprietary technologies, like the Water-Gate system, demand extreme precision. The plastic frame for the T-shaped water purification filter, for example, requires micron-level accuracy in its cavity design to ensure the perfect formation of its nano-scale water film across millions of fibers. Our mold-making achieves this, turning advanced concepts into manufacturable components.

Mastering Complex, Integrated Systems: Products like the T-Series are integrated systems. Their manufacture involves multi-material injection molds, high-gloss finish tooling, and molds for精密齿轮箱 and aerodynamic components. Creating the perfectly balanced, silent fan impeller, for instance, requires advanced multi-axis CNC machining and meticulous mold flow analysis to prevent defects.

Built for Longevity and Stability: We use premium-grade mold steels and apply specialized treatments like vacuum heat treatment. This ensures our molds withstand high-volume production cycles—often in the hundreds of thousands—while maintaining dimensional stability, which is the direct source of product durability and long-term performance consistency.

2. A Robust, Vertically Integrated Industrial System

Our mold-making excellence is powered by a complete, in-house manufacturing ecosystem.

Design for Manufacturability (DFM): Our product development and mold engineering teams collaborate from the earliest stage. Using 3D modeling and CAE software for structural and mold flow analysis, we optimize designs for production before tooling begins, ensuring reliability and efficiency.

State-of-the-Art Production & Verification: We operate advanced precision machining centers (e.g., 5-axis CNC) and complement them with a rigorous quality verification suite. This includes coordinate measuring machines (CMM) and laser scanners to validate every mold and first article against original digital designs, creating a closed-loop, data-driven quality process.

Controlled and Automated Production: The journey from mold to final part is meticulously managed. We conduct extensive trial runs to perfect process parameters. In mass production, automated injection molding cells and a Manufacturing Execution System (MES) ensure repeatable, traceable, and standardized manufacturing of every component.

3. The Tangible Outcome: Uncompromising Product Quality

This comprehensive industrial capability translates directly into the superior quality users experience.

Unmatched Consistency: Every Aimbon device, from the first to the thousandth off the line, benefits from parts with identical dimensional accuracy. This guarantees consistent sealing, airflow, and core functional performance in every unit.

Inherent Reliability and Durability: Components from precision molds fit together seamlessly, with rational structural integrity. This minimizes the risk of air leaks, operational noise, or mechanical failure over time, leading to products known for their quiet, dependable operation.

Enabling Sophisticated Innovation: Our manufacturing prowess is what makes advanced, integrated product architectures possible. It allows us to reliably produce and assemble complex subsystems—from the T-filter to ionization modules—at a commercial scale without compromising quality.

Conclusion

In summary, Aimbon’s product excellence is engineered from the ground up. It is the direct result of possessing and integrating world-class mold design and manufacturing capabilities within a robust, vertically controlled industrial framework. This deep command over the entire manufacturing process chain is our ultimate guarantee of quality, transforming innovative designs into high-performance, durable products that users can trust.